SPC Pro Achieves 51% Saving!

The brief

Our client, a leading Energy and Carbon Reduction Specialist, are metering and data logging experts so it's no surprise that Elcomponent's SPC PROs are a major part of their toolkit. However, a recent major project opportunity required an even more innovative approach than usual to work around the restrictions of the site and its operating conditions.

The energy data logger SPC PRO is usually plugged into the mains whilst logging, but it's a versatile instrument and for applications where no voltage hookup is available, its hefty internal battery provides up to 3 weeks logging. However in this instance that was not sufficient. The project was going to need at least 20 units in use simultaneously for up to six weeks, and in order to provide the necessary survey endurance to ascertain the full potential for carbon reduction, a new approach was needed.

The challenge was to double the battery life of the SPC PRO but remain within the tight cost constraints necessary to keep the project viable. It was also important that the instrument's core advantages of compact dimensions and ease-of-use in the field were not compromised as a data logger.

We needed a solution to modify our data logger

The solution came in the form of a very efficient external lithium-ion rechargeable battery pack which boosted the 'no voltage available' survey duration of the SPC PRO from three to six weeks. Integrating the additional battery pack required some modifications to the data logger which were carried out as a 'level 2 special build' during production, and took the form of a revised power supply design and a new input socket to allow the external battery to be connected.

These 'Specials' were supplied as complete kits in Elcomponent's standard zip-up case complete with all accessories and ready to start work immediately.

THE CLIENT'S FEEDBACK

the clients Operations Director takes up the story...

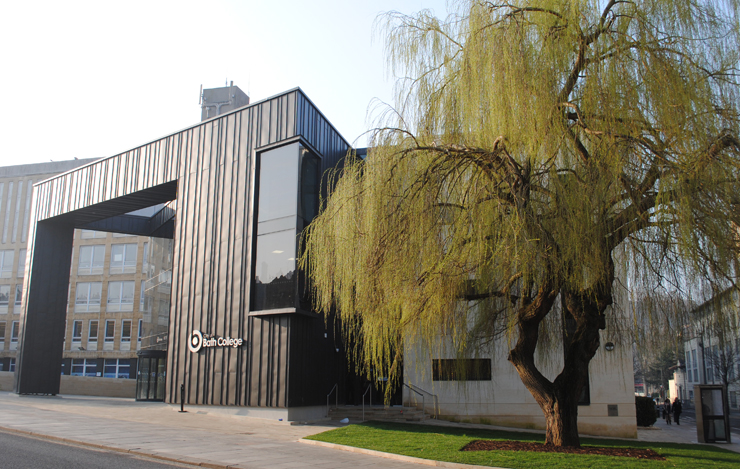

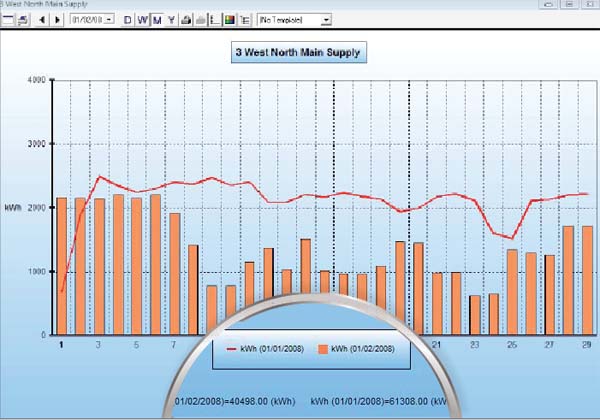

"The level of service from Elcomponent was excellent and it was really refreshing to work with a dynamic, forward-thinking, company that understands and cares about their customer needs. The SPC PRO data loggers with the bespoke modifications have already been utilised extensively throughout the MOD estate and are really proving their worth in search of carbon reduction opportunities. In one recent application 51% of HVAC energy was saved by identifying out-of hours electricity consumption. As a result of the 'Energy Mapping' exercise 13% of the total building's electricity has been saved."

Elcomponent Sales Manager Debbie Burton adds...

"I really wanted to be able to help the guys although the spec initially sounded like a tough call. In fact, the project went very smoothly - they were able to tell us exactly what they needed and we were able to agree the revised logger spec, and then sign off the design and build the units inside six weeks."